Views: 0 Author: Site Editor Publish Time: 2025-06-19 Origin: Site

One of the most critical challenges facing space solar cells is the harsh radiation environment in space. Unlike Earth, which benefits from the protective shielding of the atmosphere and magnetic field, space is filled with high-energy particles that can significantly degrade solar cell performance over time.

Two of the most damaging types of radiation encountered in space are high-energy protons and electrons. These particles originate primarily from the Sun (as solar energetic particles) and the Van Allen radiation belts, particularly in low Earth orbit (LEO), medium Earth orbit (MEO), and geostationary orbit (GEO). Over time, this radiation can penetrate solar cell materials, causing displacement damage in the crystal lattice of the semiconductor layers. This structural damage leads to reduced carrier lifetime and ultimately degrades the power output of the solar cell.

In deep space or high-altitude orbits, cosmic rays—extremely high-energy particles from beyond our solar system—further intensify radiation exposure, making the need for radiation-hardened solar cell technology even more urgent.

Understanding how radiation impacts space solar cells is crucial for selecting the right materials, cell architectures, and protective measures. Without sufficient radiation resistance, power systems may fail prematurely, jeopardizing entire space missions. Therefore, designing solar cells that can withstand long-term exposure to intense radiation is a cornerstone of modern spacecraft engineering.

Radiation in space has a direct and often irreversible impact on the performance of space solar cells. The core mechanism behind this degradation involves the interaction of high-energy particles—such as protons, electrons, and cosmic rays—with the materials and internal structure of the solar cell, particularly the PN junction, which is responsible for generating electricity from sunlight.

When energetic particles collide with the semiconductor material, they displace atoms from their original positions, creating vacancies and interstitials—collectively known as crystal lattice defects. In GaAs-based space solar cells, these defects act as recombination centers that capture free charge carriers (electrons and holes) before they can contribute to electric current. This loss reduces the carrier lifetime and significantly diminishes overall cell efficiency.

The PN junction, the heart of the solar cell where light-induced electron-hole pairs are separated, is particularly vulnerable to ionizing radiation. High-energy radiation can introduce interface states and trap charges near the junction, altering the electric field that drives carrier separation. This leads to:

A reduction in open-circuit voltage (Voc).

Decreased short-circuit current (Isc).

Lower fill factor (FF) and overall efficiency.

Over time, as more defects accumulate, the conversion efficiency of the solar cell can degrade by 20% or more, depending on the radiation dose and duration of exposure.

Radiation can also damage surface coatings, anti-reflective layers, and metal interconnects within modular panel assemblies. This may lead to increased series resistance, thermal instability, and even delamination of cell components, especially during long-duration missions.

In the context of designing durable and efficient space solar cells, one of the most important decisions is the choice of cell material. While both silicon (Si) and Gallium Arsenide (GaAs) based technologies have been used in space applications, triple-junction GaAs solar cells have proven to offer significantly better radiation resistance than their silicon counterparts.

Triple-junction GaAs solar cells consist of three sub-cells stacked on top of each other: typically GaInP (top cell), GaAs (middle cell), and Ge (bottom cell). Each layer is tuned to absorb a specific portion of the solar spectrum, allowing for more efficient light absorption and higher overall energy conversion—often above 30% efficiency.

In contrast, traditional silicon solar cells operate as single-junction devices, capturing a narrower range of wavelengths and generally achieving lower efficiencies (around 15–20% in space environments).

When exposed to space radiation (such as high-energy protons and electrons), triple-junction GaAs cells exhibit slower degradation rates than silicon cells. The key reasons include:

Direct bandgap structure of GaAs materials allows faster carrier transport and better tolerance to crystal damage.

GaAs cells generate fewer radiation-induced defects that affect performance-critical parameters like carrier lifetime and minority carrier diffusion length.

The layered design of triple-junction cells provides inherent redundancy: even if one sub-cell is slightly degraded, others can continue to produce power effectively.

Studies have shown that under equal radiation exposure, GaAs cells may retain over 90% of their initial performance, while silicon cells may drop below 70%.

Beyond radiation, space environments also impose severe thermal stress. GaAs cells have a higher temperature coefficient stability, meaning their performance remains more consistent across extreme temperature variations—an important factor for missions in LEO, GEO, or deep space.

When it comes to designing space solar cells capable of operating reliably in high-radiation orbits and deep-space environments, several key design considerations come into play. From materials science to precision engineering, every detail influences the final performance and durability of the solar cell in space.

The core of a radiation-resistant space solar cell lies in its multi-junction structure. YIM’s high-efficiency cells are built using a GaInP2/GaAs/Ge triple-junction configuration, which enables each sub-cell to absorb a specific part of the solar spectrum. This structure not only boosts power conversion efficiency to 30–32%, but also offers superior tolerance to displacement damage caused by high-energy protons and electrons.

Each of the three layers has distinct roles:

GaInP2 (top cell): Excellent for UV and high-energy visible light absorption; highly radiation-hardened.

GaAs (middle cell): Main power contributor with good efficiency and strong structural stability.

Ge (bottom cell): Captures infrared light and serves as a mechanical substrate with added durability.

Radiation resistance isn’t just about the photovoltaic layers—it also depends on smart protection strategies. YIM incorporates space-qualified cover glass to shield the solar cell surface from atomic oxygen erosion, micrometeoroid impacts, and UV-induced degradation. These glass layers are anti-reflective coated and thermally matched to the cell, ensuring both protection and performance.

Additionally, each solar cell assembly includes a discrete silicon bypass diode, which prevents reverse-bias damage and ensures electrical continuity even if part of the panel is shaded or fails. These diodes are critical in modular or large-array applications where performance uniformity matters.

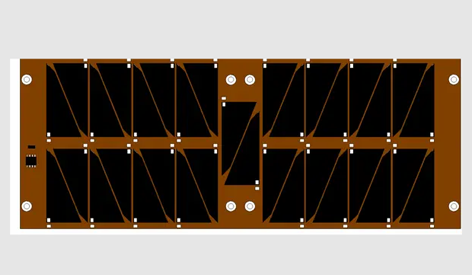

Shanghai YIM Machinery Equipment Co., Ltd. employs advanced welding, encapsulation, and interconnect technologies in its flagship SC-3GA-1 and SC-3GA-4 solar cell assemblies. These models use:

Laser-welded kovar/silver interconnectors for secure, low-resistance connections.

Radiation-hardened potting materials to maintain mechanical and electrical integrity under thermal cycling and particle bombardment.

Modular construction for integration into arrays and solar wings of various configurations.

The SC-3GA-4, in particular, features a CIC (Cell Interconnected Circuit) design and is engineered for high-efficiency, high-stability operation even in extended GEO missions or interplanetary probes.

All of YIM’s space solar cells and assemblies meet the stringent requirements of ECSS E ST20-08C, a European Cooperation for Space Standardization guideline that governs the performance and environmental resilience of photovoltaic technologies used in space. This compliance ensures:

Predictable degradation curves under known radiation doses.

Qualification for LEO, MEO, GEO, and interplanetary missions.

Compatibility with satellite power system standards worldwide.

YIM’s space solar cells are not just lab-proven—they are space-proven. Their solar cell assemblies have been deployed on a wide range of high-profile missions, including:

Beidou-3 (M12) and Beidou-42 navigation satellites.

Chang’e-4, China’s lunar lander and rover mission.

Gaofen-11, ZY-3(03) Earth observation satellites.

Moziji, Haiyang-2B, and dozens of other LEO and GEO satellites.

In these missions, YIM’s triple-junction GaAs cells have demonstrated minimal efficiency loss over extended operational periods, excellent thermal and mechanical stability, and no major degradation from radiation exposure—validating their design and engineering in real-world environments.

In the unforgiving environment of space, radiation resistance equals mission reliability. High-efficiency, radiation-hardened space solar cells like those produced by Shanghai YIM Machinery Equipment Co., Ltd. deliver the critical balance of:

High power output

Long operational life

Stable performance across orbital zones

As more space missions venture into longer orbits, deeper exploration, and high-radiation zones, the demand for robust, precision-engineered solar technology will only increase.

To ensure your satellite, rover, or deep-space probe is powered by the most trusted and space-proven solutions, explore YIM’s complete line of solar cell assemblies at www.shyimspace.com, or contact their expert team for technical consultation and product support.