Views: 0 Author: Site Editor Publish Time: 2025-06-19 Origin: Site

A space solar cell assembly is a fully integrated unit designed to convert sunlight into electrical power for spacecraft operating in the harsh environment of space. Unlike ordinary solar panels, these assemblies are engineered to withstand extreme radiation, temperature fluctuations, and mechanical stress encountered in Low Earth Orbit (LEO) and Geostationary Earth Orbit (GEO).

The main components of a space solar cell assembly include:

Solar Cells: Typically triple-junction Gallium Arsenide (GaAs) cells with layered structures such as GaInP2/GaAs/Ge. These high-efficiency cells capture a broad spectrum of sunlight and maintain performance even under intense radiation.

Welded Interconnects: Solar cells are electrically connected using metal interconnectors (usually silver or kovar) secured by precise laser welding. This ensures low electrical resistance and mechanical durability.

Bypass Diodes: Integrated silicon diodes protect the assembly by allowing current to bypass shaded or malfunctioning cells, preventing hot spots and power loss.

Cover Glass: A radiation-resistant, anti-reflective glass layer covers the cells, shielding them from ultraviolet rays, micrometeoroids, and atomic oxygen erosion, while maintaining thermal stability.

Together, these components form a reliable and efficient solar power source, critical for powering satellites and spacecraft in various orbits. Their robust design ensures long-term functionality in space missions, making space solar cell assemblies indispensable in modern aerospace engineering.

Understanding the differences between Low Earth Orbit (LEO) and Geostationary Earth Orbit (GEO) environments is crucial for designing effective space solar cell assemblies. These orbits expose solar panels to distinct challenges that directly affect their performance, durability, and power output.

In LEO, satellites orbit the Earth approximately every 90 minutes. This rapid orbit means that spacecraft frequently transition between direct sunlight and Earth’s shadow, causing extreme and rapid thermal cycling. The solar cells and their assemblies must endure temperature swings that can range from -150°C to +120°C multiple times a day. This intense thermal stress requires materials and bonding techniques that can withstand expansion and contraction without degradation or cracking.

In contrast, GEO satellites maintain a fixed position relative to Earth and generally experience much longer periods of sunlight, with fewer and slower transitions into shadow during seasonal eclipses. Although the thermal cycling in GEO is less frequent than in LEO, the temperatures can remain high for extended periods, requiring assemblies to have excellent thermal stability and heat dissipation capabilities.

Radiation exposure is another critical difference. LEO spacecraft face moderate levels of radiation due to proximity to Earth’s magnetic field, which offers some shielding. However, they are still exposed to bursts of high-energy particles from solar flares and the Van Allen radiation belts.

GEO satellites experience much harsher radiation environments. They are outside the protective blanket of Earth’s magnetosphere and subjected to intense, continuous bombardment by high-energy protons, electrons, and cosmic rays. This environment demands that solar cell assemblies use radiation-hardened materials and designs to minimize performance degradation over long mission durations, often spanning 15 years or more.

Power continuity differs significantly between the two orbits. LEO satellites experience frequent eclipses, with solar panels periodically losing sunlight as the spacecraft passes into Earth's shadow. To maintain power during these dark periods, LEO missions rely heavily on onboard batteries, making energy storage and management critical components of the power system.

On the other hand, GEO satellites enjoy near-continuous sunlight for most of the year, except during predictable seasonal eclipses lasting up to several weeks. This consistent solar exposure allows GEO solar cell assemblies to provide a stable power supply with less dependence on battery systems, emphasizing the need for long-term efficiency and durability.

When evaluating space solar cell assemblies for LEO and GEO missions, several critical performance metrics determine their suitability and reliability:

Conversion efficiency measures how effectively a solar cell converts sunlight into usable electrical power. Advanced triple-junction GaAs solar cells typically achieve efficiencies between 30% and 32%, far surpassing traditional silicon cells. High efficiency allows spacecraft to generate more power from smaller, lighter solar arrays, which is essential for reducing launch mass and costs.

In space applications, every gram counts. The power-to-weight ratio (measured in watts per kilogram) reflects how much electrical power an assembly can deliver relative to its mass. High power-to-weight ratios mean smaller, lighter solar panels without compromising output, which is especially crucial for LEO satellites with strict weight limits and for missions where launch costs must be minimized.

Space solar cell assemblies must maintain performance over long mission durations—typically 10 to 15 years or more. This requires resistance to degradation caused by radiation, thermal cycling, and micrometeoroid impacts. Assemblies that maintain at least 90% of their initial power output throughout their operational life are considered highly reliable.

The triple-junction architecture combines three semiconductor layers—Gallium Indium Phosphide (GaInP2), Gallium Arsenide (GaAs), and Germanium (Ge)—each optimized to absorb different parts of the solar spectrum. This layered design captures a broader range of sunlight wavelengths, significantly boosting conversion efficiency compared to single-junction cells.

GaInP2 Layer: Absorbs high-energy photons in the visible spectrum, offering excellent radiation resistance.

GaAs Layer: Converts medium-energy photons efficiently and provides thermal stability critical in orbit.

Ge Layer: Acts as the bottom cell, capturing lower-energy infrared photons and providing mechanical support.

The Ge substrate not only serves as the bottom cell but also offers superior mechanical and thermal stability. This stability ensures that the solar cell assembly can endure repeated thermal cycling and mechanical stresses encountered during launch and orbital operation without losing structural integrity or performance.

Combined, the GaAs triple-junction cell on a Ge substrate offers a balance of high efficiency, radiation hardness, and durability, making it the preferred choice for most space solar cell assemblies designed for both LEO and GEO missions.

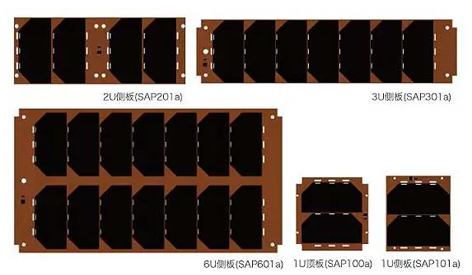

Shanghai YIM Machinery Equipment Co., Ltd. offers industry-leading SC-3GA series space solar cell assemblies tailored to meet the diverse demands of different orbital environments and mission profiles.

Designed specifically for Low Earth Orbit (LEO) applications, the SC-3GA-1 features:

High-efficiency triple-junction GaAs cells with conversion efficiencies around 30%.

Laser-welded silver/kovar interconnectors providing excellent mechanical strength and electrical conductivity, capable of enduring frequent thermal cycling.

Integrated silicon bypass diodes that protect the assembly from current blockage and hot spots caused by partial shading or cell failures.

Compact and lightweight design optimized for rapid deployment and small satellite configurations.

Optimized for Geostationary Earth Orbit (GEO) and deep space missions, the SC-3GA-4 offers:

Conversion efficiencies exceeding 32%, delivering higher power output for demanding missions.

Cell Interconnected Circuit (CIC) assembly process enhancing electrical performance and thermal management.

Enhanced radiation shielding materials and multi-layer glass encapsulation, providing superior long-term radiation resistance.

Rigorous life cycle and radiation testing ensuring over 15 years of reliable orbital operation.

Both models comply with the ECSS E-ST-20-08C European space standards, guaranteeing stable performance under extreme space conditions.

YIM maintains strict control over every manufacturing step to ensure the highest quality for its space solar cell assemblies:

Advanced laser welding technology bonds the silver or kovar interconnectors securely to the solar cells. This method ensures low-resistance electrical contacts and minimizes thermal stress-induced fatigue, critical for surviving launch vibrations and thermal cycling in orbit.

Assemblies undergo thermal vacuum (TVAC) testing to simulate the vacuum of space and extreme temperature variations. This verifies that physical and electrical properties remain stable under these harsh conditions, ensuring mission longevity.

All products are rigorously tested to meet ECSS E-ST-20-08C standards, covering mechanical shock, thermal cycling, radiation tolerance, and electrical performance retention—aligning with international aerospace mission requirements.

Selecting the right space solar cell assembly depends heavily on the mission’s orbital environment—whether it is LEO with frequent thermal cycles and eclipse periods or GEO with intense radiation and long mission durations. YIM’s mature SC-3GA series, combined with stringent testing and certification, offers tailored, reliable solutions for both orbit types.

Whether facing the challenges of rapid thermal cycling and partial shading in LEO or the high-radiation, long-duration demands of GEO, YIM delivers efficient, durable space solar power components to ensure mission success.

For more detailed product information and technical support, visit www.shyimspace.com or contact YIM’s expert team to discuss custom solutions for your space power needs.