Views: 0 Author: Site Editor Publish Time: 2025-06-19 Origin: Site

Space solar cells are the cornerstone of powering satellites and spacecraft across various orbits, from Low Earth Orbit (LEO) to deep-space missions. Among the many technologies available, Gallium Arsenide (GaAs) solar cells stand out for their high efficiency, superior radiation resistance, and excellent power-to-weight ratio. However, within GaAs technology, a crucial design choice faces spacecraft engineers and mission planners: flexible versus rigid solar cells. Both flexible and rigid GaAs space solar cells have unique advantages and limitations that influence satellite design, launch configurations, power generation capacity, and mission success.

Gallium Arsenide (GaAs) solar cells employ a compound semiconductor that offers distinct advantages over traditional silicon solar cells, especially in space environments. The multi-junction (typically triple-junction) GaAs solar cells layer different semiconductor materials to capture a broader spectrum of solar radiation efficiently. This design results in conversion efficiencies often exceeding 30%, coupled with outstanding resistance to space radiation damage.

GaAs cells’ high efficiency and durability have made them the preferred choice for many satellite missions worldwide, from communication and Earth observation satellites to exploratory deep-space probes. They operate reliably under intense ultraviolet radiation and extreme temperature cycles experienced in space.

Within the GaAs family, space solar cells come in two primary structural formats: rigid and flexible.

Rigid GaAs solar cells are manufactured on a solid, inflexible substrate—often Germanium (Ge) or other semiconductor wafers—that provides mechanical support and electrical conduction. These cells are typically mounted on stiff panels with glass or quartz cover glass for protection.

Mechanical Stability: Their sturdy construction offers excellent structural integrity, which helps maintain optimal solar cell orientation and reduces damage risks during launch and deployment.

High Efficiency: The rigid substrate supports complex multi-junction architectures with minimal strain, maximizing conversion efficiency.

Radiation Resistance: Rigid GaAs cells maintain high performance even after prolonged exposure to charged particles and cosmic rays.

Thermal Management: Solid panels facilitate heat dissipation, minimizing hotspots that can degrade solar cell performance.

Weight and Volume: Rigid panels are heavier and bulkier compared to flexible options, which can impact spacecraft mass budgets and launch costs.

Limited Folding/Deployment Options: Due to their inflexibility, rigid panels require careful packaging and deployment mechanisms, increasing mission complexity and risk.

Manufacturing Cost: The production of rigid multi-junction cells with high-quality cover glass and substrates can be expensive.

Rigid GaAs solar cells are ideal for large satellites with ample room for solar arrays and missions requiring long operational lifetimes, such as Geostationary Earth Orbit (GEO) communications satellites, weather satellites, and deep-space missions.

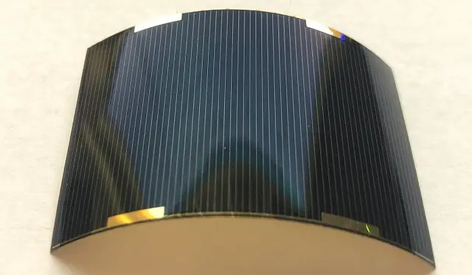

Flexible GaAs solar cells are built on ultra-thin substrates or films, allowing the cells to bend, fold, or roll without damaging their delicate semiconductor layers. Advances in materials science have enabled flexible GaAs cells with competitive efficiency and durability, opening new frontiers in spacecraft design.

Lightweight and Thin: Eliminating thick rigid substrates drastically reduces weight, benefiting spacecraft mass constraints.

Conformability: Flexible cells can be integrated onto curved or irregular spacecraft surfaces, enhancing design freedom.

Compact Stowage: The ability to fold or roll solar arrays allows for more compact payload packaging and smaller launch vehicle fairings.

Rapid Deployment: Flexible arrays can deploy quickly with simpler mechanisms, lowering mission complexity and potential failure points.

Mechanical Vulnerability: While flexible, these cells require protective encapsulation to guard against micrometeoroids, UV degradation, and thermal stress.

Thermal Management: Thinner substrates can make heat dissipation more challenging, potentially increasing risks of hot spots.

Lower Efficiency Ceiling: Though catching up, flexible GaAs cells often have slightly lower maximum efficiencies than rigid counterparts due to substrate and encapsulation compromises.

Radiation Shielding: Additional layers may be necessary to achieve radiation hardness comparable to rigid cells, which can offset weight savings.

Flexible GaAs solar cells are increasingly popular for Small Satellites (SmallSats), CubeSats, and missions with stringent mass and volume constraints or unconventional form factors. Their adaptability also makes them attractive for deployable solar sails and space stations with modular solar arrays.

Feature |

Rigid GaAs Solar Cells |

Flexible GaAs Solar Cells |

Mechanical Structure |

Solid, inflexible substrate (e.g., Ge) |

Thin, bendable substrate or film |

Weight |

Heavier due to substrate and glass |

Lightweight, minimal substrate weight |

Efficiency |

Typically 31-32% or higher |

Slightly lower, 28-31% depending on design |

Radiation Resistance |

Excellent, inherent in thick substrate |

Good but may require additional shielding |

Thermal Management |

Better heat dissipation |

More challenging due to thinness |

Deployment |

Requires complex hinge/deployment systems |

Can be folded, rolled, or conformed easily |

Packaging Volume |

Larger, rigid panels |

Compact, foldable for efficient stowage |

Application Suitability |

GEO satellites, long-term missions |

SmallSats, CubeSats, deployable arrays |

Cost |

Higher manufacturing cost |

Potentially lower cost with scalable production |

The decision to use flexible or rigid GaAs space solar cells hinges on several factors linked to your satellite’s mission profile and design constraints:

For long-duration GEO or deep-space missions with intense radiation, rigid GaAs cells offer superior durability and stable power output.

For short- to medium-term LEO missions, especially involving small satellites, flexible GaAs cells provide sufficient performance with greater mass and volume savings.

Larger satellites with less stringent mass constraints benefit from the mechanical robustness of rigid solar panels.

CubeSats and SmallSats with tight mass and volume limits gain substantial advantages from the lightweight, compact nature of flexible arrays.

If your spacecraft can accommodate complex, motorized solar panel deployment systems, rigid panels can be used effectively.

When simplicity and reliability of deployment are priorities, flexible solar cells offer straightforward folding or rolling deployment options, reducing mechanical risks.

Missions with harsh thermal cycling favor the thermal stability of rigid solar arrays.

Flexible arrays may require additional thermal design considerations but can be engineered with protective coatings and heat spreaders.

Recent breakthroughs have addressed many limitations of flexible GaAs cells:

Improved Encapsulation: Multi-layer barrier films protect flexible cells from space environment degradation.

Enhanced Radiation Shielding: Integration of thin, lightweight radiation-resistant materials extends flexible cell lifetime.

Higher Efficiency Designs: New fabrication techniques close the efficiency gap with rigid cells, now achieving efficiencies over 30% in some cases.

Modular Solar Arrays: Flexible cells can be assembled into modular arrays customized for diverse satellite geometries and power requirements.

Rigid GaAs Solar Cells:

Many GEO communications satellites, such as those in the Beidou or Inmarsat fleets, rely on rigid GaAs arrays for continuous high-power operation and longevity exceeding 15 years.

Flexible GaAs Solar Cells:

CubeSat missions like those launched for Earth observation or technology demonstrations frequently use flexible GaAs arrays to maximize power while minimizing launch mass and volume.

Both flexible and rigid GaAs space solar cells have essential roles in modern satellite power systems. The choice between them should be driven by mission-specific factors such as orbital environment, mission duration, spacecraft design constraints, and deployment mechanisms.

Rigid GaAs cells excel in providing durable, efficient, and stable power for large, long-duration missions in challenging orbits.

Flexible GaAs cells empower innovative satellite designs with their lightweight, compact, and adaptable form, making them ideal for SmallSats, CubeSats, and missions with mass and volume limitations.

By understanding these trade-offs, satellite designers and mission planners can select the optimal solar cell technology to maximize mission success and efficiency. For more information on advanced GaAs solar cells, including flexible and rigid options, explore offerings from industry leaders like Shanghai YIM Machinery Equipment Co., Ltd. Their expertise and customizable solar solutions help spacecraft meet the rigorous demands of today’s and tomorrow’s space missions.