Views: 0 Author: Site Editor Publish Time: 2025-06-19 Origin: Site

Space Solar Cells work in extreme conditions far beyond Earth's atmosphere. They face intense radiation, temperature swings, and a vacuum, while Earth-based solar panels deal with weather, dust, and changing sunlight. Engineers select materials and designs for each environment. These choices impact how much energy each system can produce and how long they last. Understanding these differences helps drive progress in solar technology.

Space solar cells use advanced materials and designs to survive harsh conditions like radiation and vacuum, while Earth panels focus on weather resistance and affordability.

Space solar cells achieve higher efficiency and continuous power but cost much more due to complex materials and launch expenses.

Earth solar panels face challenges from weather, dust, and pollution, but regular maintenance and improved designs help maintain their performance.

Durability is key: space cells last long under extreme stress, and Earth panels come with warranties of 25 years or more to ensure reliable energy.

Innovations from space solar technology often improve Earth-based panels, driving progress in clean energy for homes and businesses worldwide.

Space Solar Cells power satellites, space stations, and deep-space probes. These cells must work in harsh environments where radiation, extreme temperatures, and vacuum conditions challenge their performance. Since the 1950s, engineers have improved these cells to meet the needs of space missions. The first silicon solar cell, developed at Bell Labs, enabled the Vanguard 1 satellite to use solar power in 1958. Over time, new designs like multi-junction cells and ultralightweight materials have increased efficiency and reduced weight.

Market studies, such as the Space-Based Solar Power Market Size, Share, Growth Report, show that technology trends include advanced rectenna design and carbon fiber composites. These reports highlight the growing interest in space-based solar power, with forecasts predicting market growth from $4.7 billion in 2030 to $6.8 billion by 2040. Stakeholders include government agencies, defense, commercial companies, and technology developers.

Period | Milestone/Event | Impact on Space Solar Cells | Impact on Earth-based Solar Panels |

|---|---|---|---|

1950s | Silicon solar cell developed at Bell Labs | Enabled early space missions like Vanguard 1 | Marked a major efficiency and durability improvement |

Late 1950s-1960s | Early space exploration missions powered by solar | Demonstrated viability for satellites | Used in remote areas for telecom and water pumps |

1970s | Energy crisis spurs investment in solar R&D | Limited direct impact; remained exploratory | Improved efficiency and cost, boosted adoption |

1974 | US Solar Energy Research Act | N/A | Accelerated technology development and adoption |

Earth-based solar panels provide clean energy for homes, businesses, and utilities. These panels face challenges like weather, dust, and changing sunlight. Since the 1970s, government funding and research have helped lower costs and improve efficiency. The 1974 US Solar Energy Research Act played a key role in speeding up development. Today, solar panels use advanced manufacturing and materials to deliver reliable power across the world.

Recent industry reports compile decades of research, showing how solar power has grown from early off-grid uses to widespread adoption. These reports also discuss investment trends, new technologies, and the role of solar energy in fighting climate change. Experts note that while space solar power remains expensive and complex, Earth-based solar panels continue to improve and expand their reach.

Space Solar Cells use advanced materials to survive and perform in the harsh environment of space. Engineers often choose III-V multijunction solar cells for these missions. These cells combine several compound semiconductors, such as indium gallium phosphide (InGaP), gallium arsenide (GaAs), and germanium (Ge). Each layer captures a different part of sunlight, which helps the cell reach very high efficiency—sometimes up to 47.1% under concentrated sunlight. These cells are thin, light, and can even be flexible. Their design makes them strong against radiation and temperature swings. The manufacturing process is complex and expensive, involving steps like metal–organic vapor phase epitaxy. Some new designs use nanowire structures made from III-V materials. Nanowire solar cells can handle 10–40 times more radiation than flat films. The nanowire shape lets harmful particles pass through, which reduces damage and helps the cells last longer in space.

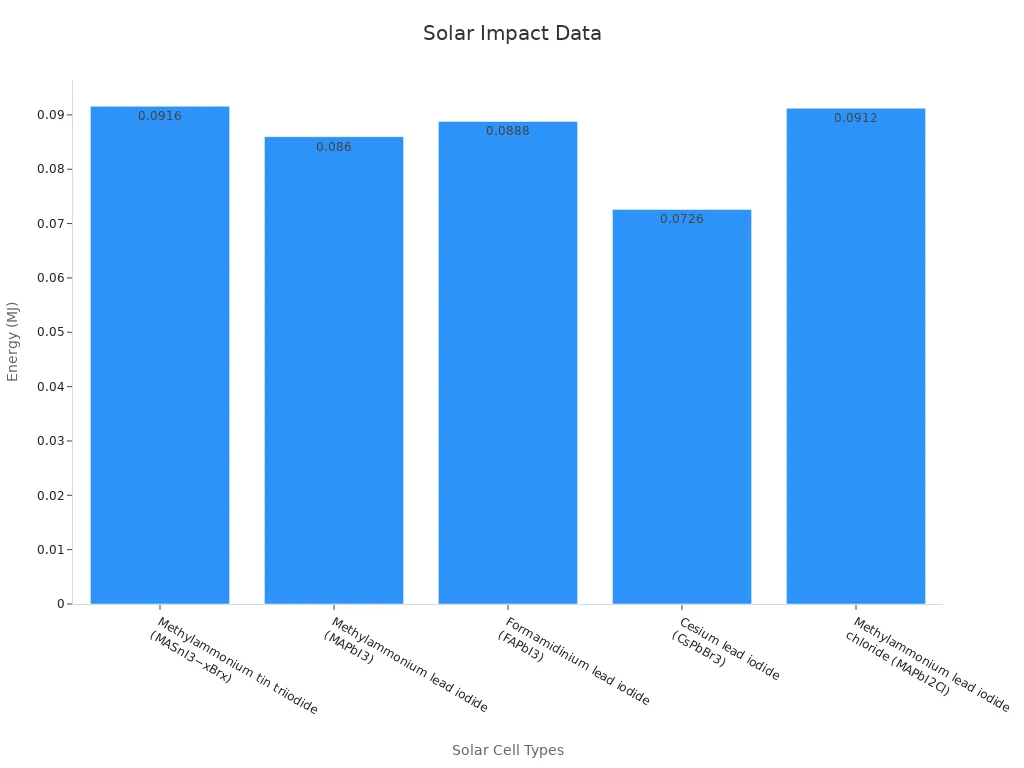

Most solar panels on Earth use silicon as the main material. Silicon solar cells are made from single-element silicon, which is doped with small amounts of other elements like boron or phosphorus. This process helps the cell turn sunlight into electricity. Silicon panels are popular because they are cheaper to make and easy to produce in large numbers. Engineers have improved silicon cells by adding new layers or using special treatments, such as ion implantation, to boost their performance. Some newer Earth panels use PERC or TOPCon technology. These designs help the panels work better and last longer, but they are still more sensitive to radiation than space cells. Perovskite solar cells are also being studied, but they need special testing for radiation hardness because their structure is softer than silicon or III-V cells.

Design choices for solar cells depend on where they will be used. Space Solar Cells must be lightweight, efficient, and able to survive high levels of radiation. Engineers often use flexible or thin designs to save weight on rockets. Nanowire and multijunction cells help protect against radiation and keep the cells working for many years. On Earth, solar panels must handle weather, dust, and changing sunlight. Designers focus on making panels strong, easy to install, and affordable. They add features like tilting mounts and protective glass to help panels last longer.

Testing standards also differ between space and Earth. Scientists use the AM0 standard to test solar cells for space. AM0 stands for "Air Mass Zero," which means the sunlight has not passed through Earth's atmosphere. This standard measures a higher total irradiance (134.8 mW/cm²) compared to the AM1.5 standard used for Earth panels (100.0 mW/cm²). The AM1.5 standard simulates sunlight at noon in the central United States, after it has passed through the atmosphere. These differences matter because the spectrum and intensity of sunlight change how well a solar cell works. Research shows that using the wrong standard can lead to errors of up to 10% in measuring performance. Space-based solar power systems can receive sunlight almost all the time, while Earth panels lose about 21% of energy due to the atmosphere and only get sunlight during the day.

Note: Space-based solar power systems can get up to three times more solar exposure than the best locations on Earth, but they face higher launch and maintenance costs.

Space Solar Cells must deliver high performance in the harsh environment of space. Engineers measure their efficiency using several key metrics. These include fill factor (FF), open-circuit voltage (Voc), and short-circuit current (Isc). The fill factor shows how well a solar cell converts sunlight into usable power. Values usually range from 50% to 82%. Multi-junction cells, which stack different materials, can reach up to 44% efficiency. Under concentrated sunlight, some advanced designs have achieved record efficiencies of 47.1%.

The National Institute of Standards and Technology (NIST) regularly tests and calibrates these cells. Their work ensures that efficiency numbers remain accurate, even when cells face radiation and extreme temperatures. In space, silicon solar cells often show slightly lower efficiency (about 14%) compared to their performance on Earth (about 16%). However, the higher amount of sunlight in space means these cells can still produce more power. Concentrator photovoltaic systems, which focus sunlight onto small, high-efficiency cells, can boost output even further.

Metric / Benchmark | Description / Value |

|---|---|

Fill Factor (FF) | 50%–82% |

Multi-Junction Cell Efficiency | Up to 44% (47.1% under concentration) |

Silicon Cell Efficiency (Space) | ~14% |

Open-Circuit Voltage (Voc) | Depends on material and temperature |

Short-Circuit Current (Isc) | Proportional to sunlight received |

Specific Power (W/kg) | High values needed for spacecraft payloads |

Radiation Hardness | Essential for long missions |

Space Solar Cells often use multi-junction designs to capture more energy from the sun. These cells work well in the AM0 spectrum, which matches the sunlight found outside Earth's atmosphere. Their high efficiency and durability make them ideal for satellites and deep-space probes.

Solar panels on Earth face different challenges. Their efficiency depends on the type of cell, the weather, and the location. Most silicon panels reach efficiencies between 10.34% and 14.00%, with an average around 13.6%. Some advanced panels in cooler climates, like Berlin, can reach up to 17.1%. High temperatures and dust can lower efficiency, especially in hot places like Dubai. In tropical areas, high humidity and pollution also reduce performance.

Region | Location | Solar Radiation (kWh/m²/day) | Efficiency (%) | Key Environmental Factors | Operational Challenges |

|---|---|---|---|---|---|

Desert | Dubai | 6.5 | 14.2 | High temperature, dust accumulation | Efficiency loss due to heat and dust |

Temperate | Berlin | 3.0 | 17.1 | Cooler temperatures | Higher efficiency despite lower radiation |

Tropical | Singapore | N/A | Lower annual output | High humidity (84%), cloud cover | Moisture and pollution reduce performance |

Researchers use computer models to predict how panels will perform in different conditions. These models show that rising temperatures can lower efficiency. Cooling strategies, such as better airflow or special coatings, help keep panels working well. The models match real-world data from manufacturers and experiments, so they provide useful guidance for improving solar panel performance.

Several factors affect how well solar cells work in space and on Earth. In space, engineers care about specific power (watts per kilogram), energy density, and how well the cells resist radiation. Multi-junction cells offer high efficiency and specific power, which helps spacecraft save weight and space. Thin film solar cells, often used on Earth, are now being adapted for space missions. These flexible designs show promise for future spacecraft.

On Earth, solar panels must handle changing sunlight, weather, and pollution. Efficiency drops when panels get too hot or dirty. In cooler climates, panels often work better, even if sunlight is weaker. Engineers use performance ratios to compare actual output to what the panel should produce under perfect conditions. This helps them find ways to improve system design and maintenance.

Tip: Regular cleaning and proper installation can help Earth-based solar panels maintain high efficiency, especially in dusty or humid environments.

Both space and Earth solar technologies continue to improve. Engineers study trade-offs between cost, weight, size, and efficiency to find the best solutions for each environment. These efforts drive progress in solar energy for satellites, homes, and businesses.

Space presents some of the harshest conditions for solar technology. Solar cells in orbit face intense radiation from the sun, including electrons and protons. Temperatures can swing from freezing cold to over 100 °C. The vacuum of space removes air, which means no protection from ultraviolet (UV) rays or sudden heat changes. These factors combine to create rapid material degradation. Microbial lethality experiments show that vacuum, solar heating, and UV light together cause strong environmental stress. The effects change depending on the spacecraft's location. Beyond Mars, vacuum and heat dominate. Beyond Saturn, vacuum alone becomes the main challenge. Over long missions, solar cells on spacecraft surfaces receive high doses of solar energy, which leads to more wear and tear. Scientists work to model and improve how solar cells resist radiation and temperature extremes.

Vacuum, solar heating, and UV rays act together to degrade materials.

Radiation-induced damage lowers efficiency over time.

The environment changes with distance from the sun.

Solar panels on Earth face different challenges. Weather, pollution, and the atmosphere all affect how much sunlight reaches the panels. Rain, snow, and dust can cover the panels and block sunlight. Pollution in the air, such as smog or dust, reduces the amount and quality of sunlight. Studies show that pollution changes the way sunlight spreads, making it less direct and more diffuse. This lowers the energy that panels can collect. In cities, pollution can cut down sunshine hours and reduce panel performance. Temperature and wind also play a role. High temperatures can make panels less efficient, while wind can help cool them.

Pollution reduces sunlight and changes its quality.

Weather events like rain and snow block sunlight.

High temperatures lower panel efficiency.

Solar Cell Technology | GHG Emissions (g CO2eq/kWh) | Key Environmental Impact Factors | Manufacturing Environment Impact |

|---|---|---|---|

Monocrystalline Silicon (m-Si) | 37.5 (Europe) to 88.7 (China) | High energy input for silicon purification; solvent emissions cause acidification | Coal-based electricity in China increases GHG by up to 80% of total impact |

Polycrystalline Silicon (p-Si) | Similar trend as m-Si | Aluminum frame and polymer layers contribute to emissions | European electricity mix reduces GHG emissions by 13-17.6% compared to China |

Cadmium Telluride (CdTe) | Lowest among studied types | Lower energy and material demand; higher toxicity due to cadmium | Toxicity concerns balanced by simpler manufacturing and lower energy use |

Engineers design solar cells to survive their environments. In space, they use special materials that resist radiation and extreme temperatures. Multi-junction cells and nanowire designs help protect against damage. These cells stay efficient even after years in orbit. On Earth, panels use tough glass and frames to handle weather. Some panels have coatings that repel dust and water. Cooling systems and better airflow help keep panels from overheating. Manufacturers also look for ways to lower greenhouse gas emissions during production. They use recycled materials and cleaner energy sources when possible.

Note: The type of solar cell and where it is made can change its environmental impact. Using less toxic materials and recycling can help reduce harm to the planet.

Solar cells in space must survive extreme conditions. NASA tested perovskite solar cells on the International Space Station for 10 months. These cells faced vacuum, radiation, and temperature swings. After returning to Earth, the space-exposed cells showed less damage than those tested on the ground. Some even regained their ability to absorb sunlight. This result shows that space-based solar cells can last longer and degrade more slowly, even under harsh stress. Engineers use special materials and designs to help these cells resist radiation and temperature changes. As a result, satellites and space probes can rely on their power systems for many years.

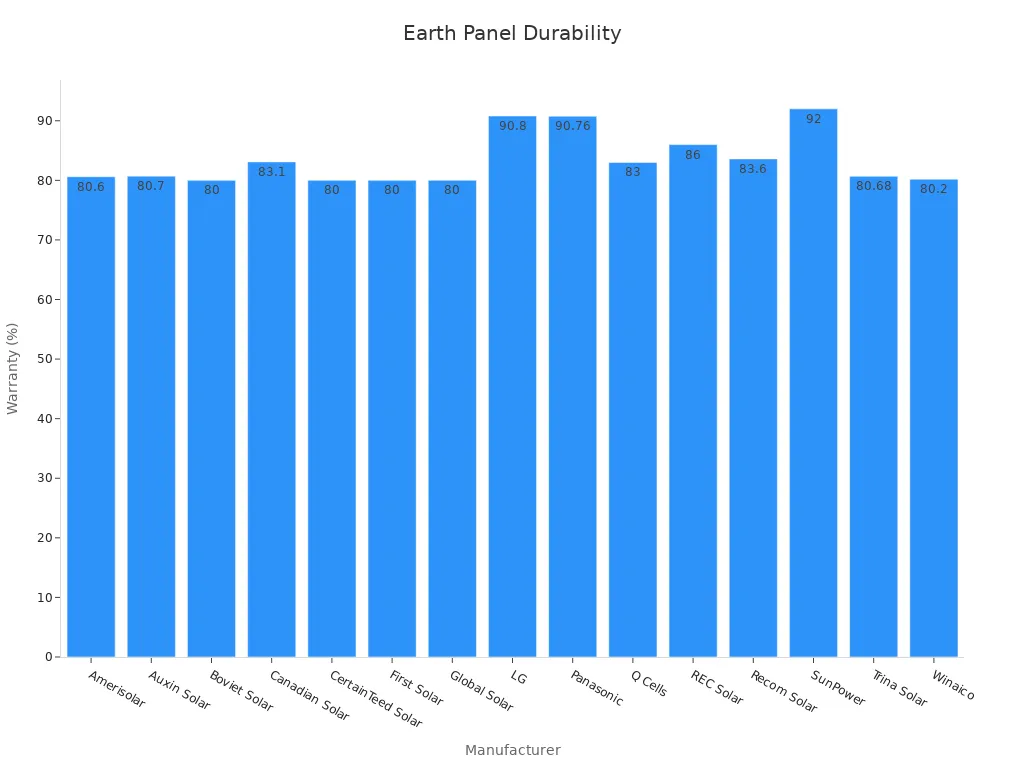

Solar panels on Earth face different challenges. They must handle rain, snow, wind, and pollution. Manufacturers test panels for durability by exposing them to heat, humidity, and sunlight over long periods. For example, researchers at Northwestern University created a barrier layer for perovskite solar cells. With this barrier, the cells kept 90% of their starting efficiency after 1,000 hours at 55°C under full sunlight. Without the barrier, the cells lasted less than 200 hours. Most commercial panels use silicon and come with power warranties that last 25 years or more. The table below shows how much power different brands promise after 25 years.

Manufacturer | Power Warranty After 25 Years (%) |

|---|---|

Amerisolar | 80.6 |

Auxin Solar | 80.7 |

Boviet Solar | 80 |

Canadian Solar | 83.1 |

CertainTeed Solar | 80 |

First Solar | 80 |

Global Solar | 80 |

LG | 90.8 |

Panasonic | 90.76 |

Q Cells | 83 |

REC Solar | 86 |

Recom Solar | 83.6 |

SunPower | 92 |

Trina Solar | 80.68 |

Winaico | 80.2 |

High-quality panels lose less power each year. Some degrade as little as 0.25% per year, while others lose up to 0.7% per year after the first year.

Space missions cannot repair or clean solar cells easily. Engineers design these cells to work for years without help. They use materials that resist damage and keep working even after long exposure to space. On Earth, solar panels need regular care. Owners clean panels to remove dust and debris. Technicians check for damage and replace faulty parts. Good maintenance helps panels last longer and produce more energy. Some new panels have coatings that repel water and dirt, making them easier to keep clean.

Solar technology for space missions comes with high costs. Launching equipment into orbit remains expensive. Current launch costs reach about $2,700 per kilogram. New rocket designs, like SpaceX Starship, could lower this to $200 per kilogram in the future. Building a 1-gigawatt space-based solar power system may require $10–$20 billion in initial investment. These systems use advanced materials and must survive harsh conditions, which adds to the price. Governments and private companies invest together to share risks and rewards. Funding comes from NASA, the European Space Agency, and China, among others. These investments help drive research and lower costs over time. The return on investment for space solar projects takes decades, but experts believe future systems could deliver much more energy per dollar than today.

Solar panels on Earth cost much less to install. Manufacturing and installation have become cheaper due to mass production and better technology. Most homes and businesses can install solar panels for a few thousand dollars. Maintenance costs stay low because panels last for decades and need little care. Government incentives and subsidies help make solar energy more affordable for families and companies. However, energy output depends on weather and daylight, which limits how much power these panels can provide.

Both space-based and terrestrial solar power have unique economic effects. The table below compares key aspects:

Aspect | Space-Based Solar Power (SBSP) | Terrestrial Solar Energy |

|---|---|---|

Solar Panel Efficiency | Higher efficiency (no atmospheric loss) | Lower due to clouds and pollution |

Operational Hours | ~99% uptime (continuous sunlight) | ~25–30% (weather and daylight dependent) |

Transmission Efficiency | 10–15% now, could reach 50–80% | N/A |

Degradation Rate | <1% per year | 0.5–1% per year |

Launch Costs | $2,700/kg now, $200/kg possible | N/A |

Initial Capital Cost | $10–$20 billion per GW | Lower, but supply is intermittent |

Energy Output per Investment | Projected 10x more by 2050 | Baseline |

Market Projection | $50–$100 billion by 2040 | Growing, well-established |

Government Investment | NASA, ESA, China | Various subsidies |

Long-Term Energy Share | Up to 20% of global energy by 2070 | Significant, but limited by intermittency |

Advances in rocket technology, modular satellite designs, and wireless power transmission could make space-based solar power more practical and affordable. Public and private partnerships, along with government support, play a key role in making these projects possible.

Space missions rely on solar technology for power. Satellites, space stations, and deep-space probes use solar arrays to run their systems. One important example is the Asgardia-1 CubeSat. This small satellite used flexible, high-efficiency solar cells from Alta Devices. The cells provided about 24 watts of power and fit easily onto the CubeSat’s structure. Teams from Twiggs Space Lab, NearSpace Launch, and NanoRacks worked together to make the mission a success. The solar cells handled the challenges of space, such as radiation and limited space for equipment. This case shows how Space Solar Cells help both educational and commercial missions reach their goals.

Caltech’s 2023 mission tested a new solar array and microwave transmitters in space. The team faced problems with cables and moving parts, but ground controllers fixed these issues using cameras and vibration. The mission proved that space-based solar power systems can work in real conditions. These tests help scientists learn how to build larger systems in the future.

Year | Mission/Project | Key Outcome |

|---|---|---|

2020 | Air Force X-37B | Demonstrated microwave power beaming from space |

2023 | Caltech Deployment | Validated power beaming and solar array function |

On Earth, solar panels power homes, schools, and businesses. People use them to lower energy bills and reduce pollution. Solar farms supply electricity to entire communities. Portable solar panels help in remote areas where power lines do not reach. Many cities use solar panels on rooftops and parking lots. These panels must handle weather, dust, and changing sunlight. Engineers keep improving designs to make them last longer and work better in different climates.

Innovations from space often improve solar technology on Earth. Flexible solar cells, first used in satellites, now appear in portable chargers and building materials. Research on radiation resistance helps make panels more durable in harsh environments. Wireless power transmission, tested in space, could one day send solar energy from space to Earth. These advances show how space missions drive progress in clean energy for everyone.

Space missions inspire new ideas and help make solar power more reliable and affordable for people around the world.

Space and Earth solar panels work in very different environments. Space panels face radiation and vacuum, while Earth panels deal with weather and pollution. Scientists test solar cells on the International Space Station to measure how well they work in space. Reports show that new technology in space can help the environment and economy on Earth. Understanding these differences helps engineers build better solar systems for the future.

Space solar cells use rare materials and advanced designs. Engineers must test them for radiation and extreme temperatures. Launch costs add to the price. These factors make space solar cells much more expensive than panels used on Earth.

Earth-based panels cannot survive in space. They lack protection against radiation and temperature swings. Space missions need special cells that resist damage and keep working for years.

Satellites and spacecraft have strict weight limits. Lighter solar cells help save fuel and lower launch costs. Engineers design space cells to be thin and strong, so they fit these needs.

Engineers use the AM0 standard to test space solar cells. They expose the cells to vacuum, radiation, and temperature swings in labs. These tests show how well the cells will work in orbit.